Solución probada. Radicalmente mejorada.

PXT™ es una innovadora tecnología de inspección de alimentos que permite a los procesadores obtener imágenes de resolución mucho más alta y capturar datos más detallados sobre el producto que se inspecciona de lo que antes era posible. Cuando estas imágenes se procesan instantáneamente, verá un aumento en la precisión de la detección y una reducción significativa de las tasas de falsos rechazos.

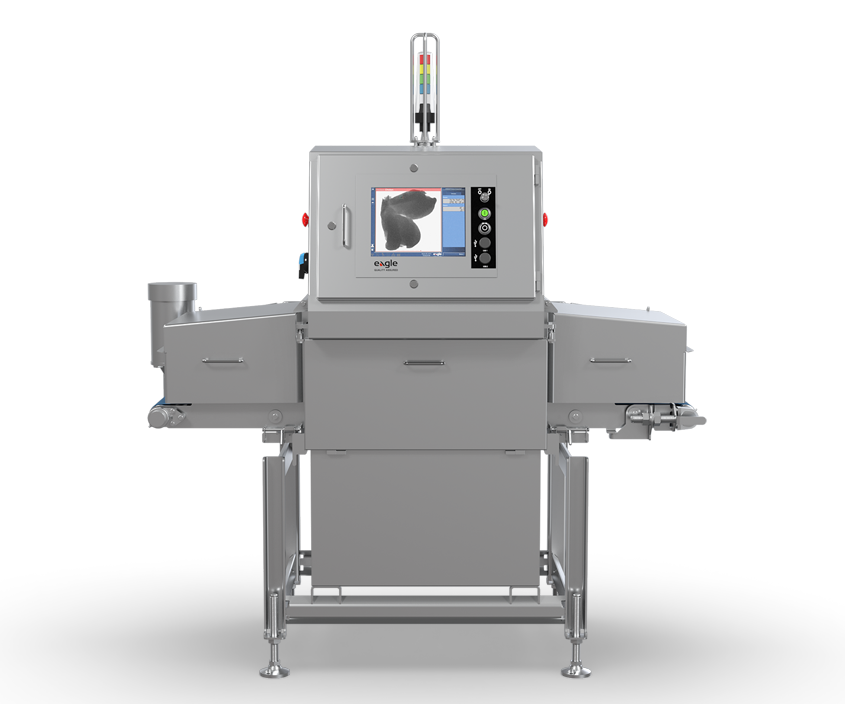

Las máquinas de rayos X Eagle equipadas con la tecnología de detección PXT™ y SimulTask™ PRO brindan el nivel más alto de detección automatizada de huesos y metales en línea de la industria y, al mismo tiempo, realizan controles de calidad e integridad del producto. Los dispositivos de rayos X Eagle equipados con tecnología PXT™ pueden funcionar en puntos de control críticos independientes o conectarse en red para permitir la optimización completa del proceso y el análisis de la eficiencia.

¿NO ES CREYENTE? ¡Véalo usted mismo!

Solicite una prueba de producto

¡Vea usted mismo los beneficios de la detección de energía dual y regístrese para una prueba de producto gratuita!

"*" señala los campos obligatorios

Inspeccionar más y Detectar más con PXT™

Como pionero en la inspección de carnes y aves, Eagle PI ofrece soluciones avanzadas de detección e inspección por rayos X en línea. Con la nueva e innovadora tecnología PXT™ de Eagle, los procesadores pueden lograr una seguridad superior del producto y un control de calidad de los alimentos garantizado, al mismo tiempo que se benefician del costo total de propiedad más bajo.

Durante más de 20 años, la experiencia de Eagle en tecnologías de energía simple y dual ha sido el estándar comprobado en detección de rayos X en toda la industria alimentaria mundial. El detector PXT™ más nuevo de Eagle es el último avance para la inspección por rayos X. Esta tecnología ofrece un rendimiento comprobado significativo para una detección superior de huesos y otros contaminantes para una amplia gama de aplicaciones de aves, mariscos y carnes.

El siguiente paso en Inspección de doble energía

La combinación de equipos construidos higiénicamente que resisten los rigores de la operación diaria, al mismo tiempo que funcionan con las tecnologías de inspección más avanzadas disponibles, proporciona la fórmula para un tiempo de actividad máximo, cumplimiento de estándares de seguridad y garantías de garantía de calidad.

Detección sin precedentes

PXT™ es un detector innovador que ofrece un salto cualitativo en el rendimiento de la inspección por rayos X. El detector PXT™ captura datos utilizables más detallados sobre el producto que se está inspeccionando de lo que era posible anteriormente, proporcionando la capacidad inigualable de detectar metales y huesos en diferentes etapas de su proceso de producción.

Reducir los falsos rechazos

Los datos de calidad superior del detector PXT™, cuando se combinan con el software avanzado de análisis de imágenes SimulTask™ PRO de Eagle, que utiliza el rango de escala de grises más alto de la industria de 0-65,535 valores, crea la imagen de mayor resolución para reducir significativamente las tasas de falsos rechazos, lo que lleva a una nuevo estándar de la industria en precisión de detección.

Bajo coste total de propiedad

Las máquinas fáciles de operar equipadas con PXT™ aumentan el tiempo de actividad, mejoran la eficiencia y el rendimiento de la línea para ofrecer el costo total de propiedad más bajo. Adecuado para carne fresca o congelada, Eagle ofrece máquinas diseñadas higiénicamente para inspección de uno o varios carriles que garantizan una detección precisa y resultados confiables.

Industria Recursos

Experimente el futuro de la inspección de materias primas para huesos de aves de corral

MAXIMIZER RMI es la solución más avanzada y eficaz del mercado avícola para la inspección de materias primas.

Pechugas de pollo en bandejas

Descubra cómo un equipo de inspección por rayos X de diseño higiénico puede proporcionar una detección precisa de abanico calcificado, deseo y hueso de costilla para las pechugas de pollo en bandejas.

SimulTask™ PRO – Carne y aves de corral

Descubra SimulTask™ PRO, el software superior de análisis de imágenes de rayos X para la inspección de carne y aves de corral.

.svg)