2025 has been a fast-moving year for the food industry, especially as far as inspections, safety, and quality are concerned. Not only are consumer demands higher than ever, but regulations are also becoming more and more stringent by the day. Meeting these demands requires food producers, processors, and retailers to undertake drastic, often transformative changes to their approach to food safety. In today’s blog, we’ll be taking a look back at how 2025 has shifted the landscape of food safety with an emphasis on traceability and due diligence capabilities.

FSMA Regulatory Updates

2025 Import Fee Updates

FSMA Rule 204: Requirements for Additional Traceability Records for Certain Foods

Record Keeping Across The Supply Chain

Rule 204 Compliance Deadline in Limbo

Technological Advancements

AI in Food Inspection Technology

Consumer Demands & Due Diligence

FSMA Regulatory Updates

The FDA made many major moves in 2025 that will undoubtedly change the food safety inspection industry for good. We’ve included a couple of the most standout points to highlight below. For a more in-depth look at the full scope of 2025 activities regarding the Food Safety Modernization Act (FSMA), be sure to read the full blog, Comprehensive FSMA Updates and Guidelines from the FDA.

2025 Import Fee Updates

In accordance with FSMA, the FDA announced updated annual fee rates for two food quality control programs: the Voluntary Qualified Importer Program (VQIP), and the Accredited Third-Party Certification Program (TPP). These rates will continue to be updated annually for the foreseeable future.

FSMA Rule 204: Requirements for Additional Traceability Records for Certain Foods

The FSMA has been in development for well over a decade, and yet, 2025’s latest updates have still managed to drastically shake up the status quo. In particular, the final ruling on Rule 204, Requirements for Additional Traceability Records for Certain Foods, has officially set in stone that many food businesses will have to step up both their food safety inspection capabilities and their record keeping practices. This can involve anything from installing new inspection points throughout a given production line to establishing and maintaining a database of food safety inspection records.

Record Keeping Across The Supply Chain

Thanks to FSMA Rule 204, supply chain networks have also been poised to become more closely integrated than ever before. Facilities are now required to monitor not just their own records and quality control methods, but those of their partners across the supply chain as well. When looking upstream, this requirement is meant to reduce the chances of any out-of-spec product slipping through the cracks. This increases accountability at every stage of the supply chain, ideally resulting in a near-ironclad approach to food quality assurance. As these regulations become tighter, it will be crucial for these businesses to adopt effective recordkeeping practices and invest in assistive technologies where applicable.

Eagle machines are designed for ease of use and seamless integration with your processes, for example proprietary software like TraceServer™ empower food producers and processors to do more with their data. Not only do our systems help food businesses keep up with the industry’s biggest changes, they help future-proof operations with reliable inspection and data centralization for the years ahead.

Rule 204 Compliance Deadline in Limbo

Rule 204 was finalized to go into effect on January 20, 2023. A compliance deadline was then slated for January 20, 2026, requiring 100% compliance from businesses across the nation (and any of their global suppliers) by that date. However, in August 2025 the FDA proposed to extend the compliance date 30 months out, to instead take effect on July 20, 2028. Naturally, this extension would give many businesses a greater chance at achieving compliance within the allotted time. There was a brief comment period for the extended compliance deadline which closed in September. As of late November 2025, a final call on the extension has yet to be announced. With the deadline still hanging in limbo, it would be wise of food businesses subject to traceability requirements to start implementing solutions sooner rather than later.

Need a hand to become compliant with FSMA Rule 204? Find out how Eagle PI systems help simplify FDA food safety inspections, record keeping & more. CONTACT US >>>

Technological Advancements

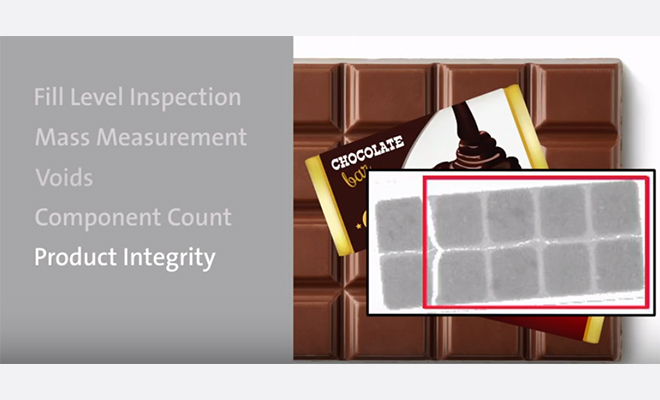

AI in Food Inspection Technology

AI remains a hot button topic across all industries, and food safety inspection is no exception. Although the newness of AI technology leaves much room for exploration, one thing has become abundantly clear in 2025: AI can only be as good as the data it has access to. With this in mind, it has never been more important for food businesses

to begin taking a hard look at their own in-house data. This involves not just collection, but also organization and comprehension. Business should ask themselves, “Do we have enough data to train an AI model? Is it the right data?” While taking a look at existing data can be a tremendous help to begin building a trustworthy and relevant database, doing so can also help identify gaps in existing processes where data collection could be beneficial.

Although no new updates have been released to the public yet, Eagle has been thoroughly researching how AI can be implemented into new and existing systems to further enhance contaminant detection capabilities for greater food safety. For more information about the role of AI in today’s food inspection technology, check out our blog post, AI and Food Safety: Today’s Challenges, Tomorrow’s Solutions. As for what to expect in 2026, the Eagle team is cooking up something extraordinary with exciting announcements coming soon.

Ready to see what our inspection and software solutions can do for you? Schedule your no-cost consultation today! CONTACT US >>>

Consumer Demands & Due Diligence

As regulatory compliance becomes more demanding, consumer quality and traceability demands are also on the rise. Although meeting regulatory demands is required by law, meeting consumer expectations often means going above and beyond for food businesses. Because of this, retailers’ demands are to meet consumer demands and thereby protect their own brand reputation.

Looking towards the future, the way to gain and maintain the trust of both customers and retailers is going beyond the demands of food safety regulations and performing due diligence which requires food businesses to answer not just the what, but the why behind their choices. As an example, more and more businesses have begun to adopt x-ray inspection machines not just at the end of their packaging lines, but at multiple points throughout their process to identify and eliminate contamination risks as soon as possible. Just having the system in place is only one part of the puzzle, though.

The other part is transparency. This transparency is driven by a proactive approach to quality and safety monitoring, risk management, and external communications. When a business has access to critical data surrounding instances of food contamination, transparency becomes that much easier to practice in crucial moments.

See the Eagle Difference

Test your product to see for yourself.

"*" indicates required fields

.svg)