Fact vs Fiction of X-ray Machine Safety

Food manufacturers use x-ray inspection because it detects a wide range of foreign materials, as well as performs inline quality checks like mass measurement and fill level. However, the word “radiation” often creates concern among plant workers and consumers. Eagle reveals the facts regarding radiation safety of x-ray machines and exposes the misconceptions in this X-ray Inspection Report.

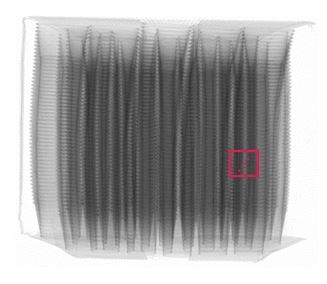

For example, learn how Eagle’s fully enclosed x-ray cabinets are designed to keep radiation contained within the system. Unlike radioactive sources, these units generate x-rays electrically and only when operational, immediately stopping if powered off or accessed. Radiation exposure outside the machines is negligible, far less than everyday environmental sources like air travel, ensuring employee safety without compromising detection performance.

This report explains:

- Why x-ray inspection is used and why it raises safety questions

- If x-ray inspection changes the food or affects production quality or compliance

- Radiation exposure and the safety of x-ray systems in a processing environment

- Whether the bigger risk to processors is radiation or undetected contaminants and recalls

- How x-ray systems maintain safety while delivering higher detection performance than other inspection technologies

See the Eagle Difference

Put our technology to the test and send us your product to witness the power of our technology for yourself.

"*" indicates required fields