for Bulk Applications Deflection Flap Reject

Removes unpackaged bulk products from production lines identified as non-conformant with quality specifications.

Removes unpackaged bulk products from production lines identified as non-conformant with quality specifications.

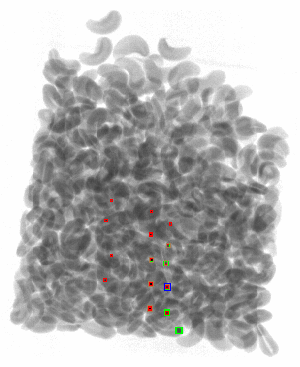

The Deflection Flap reject device consists of pneumatic cylinders that pivot multiple flaps which create an opening to drop the non-conformant bulk product in the direction of the reject receptacle. The Deflection Flap reject mechanism is specifically designed for bulk applications such as nuts, beans, peas, coffee and sugar. Deflection flap rejects are available in 1, 2, 4, 6 and 8 lane configurations.

Reject dimensions are dependent on machine type and will match machine conveyor width

Up to 60 MPM (196 FPM)

24VDC control signal supplied by the Eagle X-ray machine

IP65 standard, IP69 optional

5.5bar (80 PSI) 3/8” customer supplied dry and filtered air line, includes pneumatic control package with regulator, filter, dump valve, and low air pressure sensor; 10mm air line available upon request

For use with dry bulk flow product, product depth must conform to inspection beam geometry to enable proper operation

Multiple lane flap rejects are available so that the entire product flow does not need to be rejected when a contaminant is detected

Eagle Bulk 415 and Bulk 540 PRO

Eagle recognizes the importance of using the most robust, hygienic meat inspection and fat analysis systems that are easy to manage, and can adapt to your unique product line. From recipe management for ground products with FA or case inspection for sausages, our red meat inspection systems provide accurate and reliable results that are achieved consistently on processing lines regardless of throughput levels and environments.

Eagle provides advanced x-ray technologies and inspection systems for a variety of poultry applications, from the receipt of bulk-flow raw product, through in-process to final packaged product. Our hygienically constructed x-ray machines are suited for a variety of poultry applications. Discover our broad range of solutions with significant proven performance for superior detection of bones and other contaminants.

Catch and remove contaminants before they pose problems with Eagle’s hygienically constructed equipment. Our advanced inspection systems and breakthrough PXT™ detector technologies, help seafood manufacturers inspect more, ensuring superior quality while optimizing business performance. Applications include frozen fish fillets or blocks, canned or metalized pouches and bulk shelled products.

Eagle’s advanced inspection systems meet 3-A Sanitary Standards and can detect foreign contaminants in a multitude of dairy products, from raw cheese blocks to packaged yogurts. Our hygienically constructed equipment built to sanitary design can also ensure proper portioning, placement of product, weight and package integrity to deliver the safest, highest quality products.

Whether it’s detecting glass fragments in glass jars of jelly, plastic in a frozen bag of corn or metal in the bottom of a pickled vegetable jar, Eagle x-ray systems provide outstanding detection. With advanced dual energy technology our systems can detect contaminants in dense foods, such as dried bulk fruit, and generate easy-to-read images for enhanced analysis.

Eagle’s inline x-ray inspection systems provide exceptional detection and removal of foreign contaminants for food and beverage. Our advanced technology increases production productivity and saves manufacturing costs by simultaneously performing quality checks. Choose your industry below to learn how Eagle systems will enable you to comply with food regulations and reduce the risk of product recalls.

SimulTask™ PRO, short for Simultaneous Tasking, is Eagle’s advanced x-ray image analysis software and is the basis for all our operator-friendly x-ray inspection systems. With the highest greyscale range of 65,535 values, you will see deeper contrast and subtle differences that provide superior image results.

The Eagle TraceServer™ x-ray software program records valuable production data and machine status information from one or more of Eagle’s x-ray machines and consolidates it into a single centralized database. This intelligent software provides companies with due-diligence capabilities to enhance product traceability and overall quality assurance.

Exclusive to Eagle, this radically enhanced dual energy detector captures more detailed information about a product than previously possible. When this product information is instantly processed by Eagle’s advanced image analysis software, SimulTask PRO™, you’ll see higher resolution images, an increase in detection accuracy and significantly reduced false reject rates.

Material Discrimination X-ray, MDX is Eagle’s original dual energy technology that provides better detection for objects that show a very small x-ray absorption variation. Dense foreign bodies in dense products are more easily detected using MDX compared to single energy detectors.

In addition to providing industry-leading technology and unparalleled reliability, Eagle provides highly-responsive support and service coverage globally, through a network of expert partners, supported by a core team of regionally-based Eagle experts.

Integrating x-ray inspection technology improves Higos El Pajarero’s contaminant detection capabilities and helped to strengthen its brand protection

Find out how the Bulk 415 PRO locates contaminants and lessens products waste with advanced x-ray technology and automated reject mechanisms.

Find out how dual energy MDX technology helps bulk black bean processors locate hard to find contaminants and minimize the loss on good product.

Spanish figs manufacturer explains how they have improved the stone detection capability within bulk figs by integrating an Eagle™ Bulk 415 PRO in their production line

What Our Clients Are Saying