Adopting a new packaging design for your product can be an exciting move for any food brand or product. While a fresh look may attract more attention on grocery store shelves, it’s important to consider how a packaging transformation can inadvertently change the performance of your safety inspection systems. Innovations in packaging for foods and beverages—which are designed to attract end user attention—can pose new challenges or impact the way inspection and quality checks have previously been performed. So, let’s dive into some of those challenges and discover how Eagle’s advanced x-ray systems can accommodate multiple new packaging formats while maintaining speed, efficiency, safety, and quality.

Why Update Inspection for New Packaging Styles

Your new packaging looks different, which makes it stand out in a competitive marketplace. But an innovative new packaging format may also require a different approach in the inspection of contaminants and in steps you take to ensure quality and consistency. Not all inspection technologies are created equal, and some leave bigger gaps than others. Some of the most common customer challenges we have encountered include making the shift to glass packaging or metalized pouches.

Contaminant Detection for Glass Containers

Non-traditional geometries of glass containers, including jars and bottles, are one example of an aesthetically pleasing, yet tricky to inspect packaging format. With designs that can vary from round to square or that have octagonal structures, such vessels often have blind areas or corners where potential contaminants can lurk.

To detect and reject those hard-to-find foreign bodies, Eagle offers advanced x-ray technologies, such as the Eagle QuadView system, with four-view detection coverage in jars and bottles on high-speed lines.

The QuadView inspects packaged goods for metal, stone, glass, dense plastic, and calcified bone. Beyond contaminant detection, this technology can also be used to verify fill level, measure headspace, and verify component presence or absence. Read the application note to learn more about how the QuadView is used in glass containers.

Discover how an Eagle™ system helped one manufacturer improve their efficiency and gain the ability to detect glass-in-glass. READ THE CASE STUDY >>>

In addition to sometimes complex geometries where foreign bodies can hide, glass packaging also presents a higher risk of chipped vessels and glass shard contaminants. Many systems do not have the ability to identify contaminants of the same material as the packaging itself—especially those as small as glass shards—which can lead to nearly invisible hazards making their way through multiple quality checks.

To avoid letting products containing such hazards make their way into the hands of a consumer, it is crucial to understand that dual x-ray can help identify these otherwise untraceable contaminants. A step above single x-ray technology, dual x-ray MDX discriminates materials not just by their shape but by their atomic number for unmatched detection capabilities. Then there is PXT™, Photon-counting X-ray Technology, a dual energy detector which offers enhanced detection and enables processors to obtain much higher resolution images for superior bone and contaminant detection.

Contaminant Detection for Metal Pouches

Metalized pouches are another example of an emerging packaging format that helps increase shelf life and enhance appearance. However, it comes with its own set of challenges that traditional inspection systems commonly struggle with. Metal detectors, for instance, are entirely out of the question as they would not be able to distinguish the package from its contents. Similarly, vision systems are ineffective for inspecting the contents of an opaque pouch. X-ray systems are more effective in finding contaminants in such packages than metal detection and vision systems, while also capable of performing quality checks that enable a manufacturer to deliver safe, quality products with a lower cost of ownership

Find out how another manufacturer deployed Eagle’s x-ray technologies to ensure the safety and quality of their product in metalized pouches. READ CASE STUDY >>>

Protect Your Bottom Line

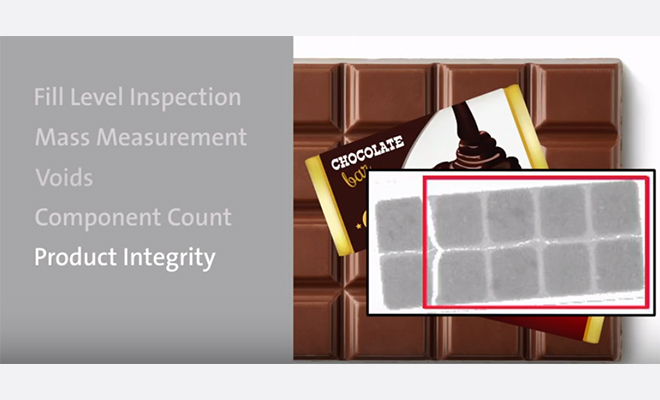

Beyond safety, there are many reasons to evaluate your inspection capabilities when making the switch to a new packaging format. Product integrity is one such reason. Your product may be safe, but are you consistently reaching the correct product count or fill level? How big of a variance is there between different units of the same product? If you’ve been using a visual system, it might be rendered useless if your new packaging obscures the view. However, x-ray can help quickly identify these quality indicators even through obscure packaging, or with complex products of varying densities.

You may discover inefficiencies that put a cap on your max throughput, especially if you are using an outdated system. An outdated system can also put your company at risk of falling out of regulatory compliance, as FSMA guidelines become more and more stringent. Taking a proactive approach to food packaging inspection can help you stay ahead, so you can focus on your production rather than worrying about playing catch up. In the end, it all boils down to taking every step to protect your bottom line today, tomorrow, and for the foreseeable future.

Prepare for Future Packaging Updates

While addressing inspection needs for today’s latest packaging is undoubtedly important, it’s also worth looking ahead to future packaging redesigns. Implementing x-ray technology on your production line can help you on both fronts. X-ray inspection technology is extremely flexible and has the ability to adapt to your needs even as your food packaging goes through different iterations.

Unlike other inspection methods which are challenged by certain materials, x-ray serves as a tool for food packaging inspection for various formats. X-ray inspection is also highly scalable, serving as a solution to maintain inspection efficiency even as your production capacity grows. If you plan on going through a new packaging iteration in the coming years, or even if your current packaging presents you with unique inspection challenges, dual x-ray tech is a tool that can help you stay prepared for anything.

See the Eagle Difference

Test your product to see for yourself.

"*" indicates required fields

.svg)