Pack 240 PRO High-Speed X-Ray Inspection Machine

Designed with advanced inspection technologies made powerfully for high-speed flow-wrap lines, blister packs and small packaged products.

Designed with advanced inspection technologies made powerfully for high-speed flow-wrap lines, blister packs and small packaged products.

Equipped with state-of-the-art inspection solutions, the Pack 240 PRO is an x-ray machine capable of providing precise and accurate detection for a wide range of products. Our x-ray inspection equipment is suitable for inspecting standard poly-wrapped products, as well as foods packaged in foil or metalized film.

The Pack 240 PRO offers the ability to perform quality inspections simultaneously, deliver superior contaminant detection and automatic rejection of the following foreign objects in the Food, Pet Food and Pharmaceutical/Personal Care industries:

242 mm (9.5″) wide at the belt, 162 mm (6.4″) wide at the top of aperture; 101 mm (4″) overall height

SimulTask™ 4 PRO standard inspection modes include contaminant, bone, missing item, clip, void, premium, shape/size, position, fill level, count, zonal mass, mass measurement with 2, 3, or 5 zone checkweighing functionality with statistics

15″ TFT color touch screen; Windows 10 Enterprise LTSB with Eagle SimulTask™ 4 PRO Control & Imaging Software; TeamViewer™ service tool for remote machine diagnostics & product set-up services

298 mm (11.8″) wide belt by 1341 mm (52.8″) long with no reject; 1626 mm (64″) long with 1 reject; 1932 mm (76.7″) long with 2 rejects

24VDC Signal only, integrated or remote mounted airblast or push arm, free standing lift or drop gate, custom rejects

17 – 114 MPM (55 – 375 FPM), subject to generator & detector used, product type & dimensions

Hi-Ray 7: 70kV @ 1mA; EA100: 70kV @ 1.25mA; or EA420: 70kV @ 3mA x-ray generators

0.4 mm, 0.4 mm PXT™ dual energy photon-counting, 0.8 mm, or 1.2 mm pitch single energy detector.

(2) USB 2.0 ports, (1) Ethernet 10/100/1000 mbps port, (1) RS232 serial port; (1) EtherNet/IP Fieldbus interface port optional

IP65 Standard, IP66 Optional; Type 304 Stainless Steel bead blasted finish

X-ray emissions <1 uS/hr; compliant to 21 CFR 1020.40, 21 CFR 179.21, & EURATOM EU nationalized standards

Compliant with CAT-3 (EN954), PLd (EN13849) safety circuits with system visualization

Air conditioner thermal management system externally mounted to rear access panel

0°C to 40°C (32°F to 104°F) 25% to 90% relative humidity non-condensing

230 VAC, +/-10%, Single Phase, 50/60 Hz, 16 Amp Fused

Multilane inspection, dynamic product changeover, encoder operation, Ethernet-IP fieldbus interface,

TraceServer™ network database software

Eagle recognizes the importance of using the most robust, hygienic meat inspection and fat analysis systems that are easy to manage, and can adapt to your unique product line. From recipe management for ground products with FA or case inspection for sausages, our red meat inspection systems provide accurate and reliable results that are achieved consistently on processing lines regardless of throughput levels and environments.

Eagle specializes in delivering top-tier x-ray inspection systems with dual energy photon-counting technology tailored for poultry processing plants. Prioritizing food safety, our x-ray detectors feature enhanced sensitivity to ensure superior detection accuracy. Our inspection equipment can identify even the smallest contaminants that might be overlooked by traditional methods like metal detectors or visual inspections, safeguarding product quality and consumer safety.

Catch and remove contaminants before they pose problems with Eagle’s hygienically constructed equipment. Our advanced inspection systems and breakthrough PXT™ detector technologies, help seafood manufacturers inspect more, ensuring superior quality while optimizing business performance. Applications include frozen fish fillets or blocks, canned or metalized pouches and bulk shelled products.

Eagle’s advanced inspection systems can detect foreign contaminants in a multitude of dairy products, from raw cheese blocks to packaged yogurts. Our hygienically constructed equipment built to sanitary design can also ensure proper portioning, placement of product, weight and package integrity to deliver the safest, highest quality products.

Whether it’s detecting glass fragments in glass jars of jelly, plastic in a frozen bag of corn or metal in the bottom of a pickled vegetable jar, Eagle x-ray systems provide outstanding detection. With advanced dual energy technology our systems can detect contaminants in dense foods, such as dried bulk fruit, and generate easy-to-read images for enhanced analysis.

Eagle’s inline x-ray inspection systems provide exceptional detection and removal of foreign contaminants for food and beverage. Our advanced technology increases production productivity and saves manufacturing costs by simultaneously performing quality checks. Choose your industry below to learn how Eagle systems will enable you to comply with food regulations and reduce the risk of product recalls.

X-ray inspection technology provides a powerful, multi-faceted approach to quality control. Beyond simply detecting contaminants, it enables simultaneous verification of various critical quality parameters in a single inspection pass. These include precise component counting to ensure product completeness, accurate assessment of fill levels to maintain consistency, and thorough evaluation of package integrity. Download the white paper to learn how x-ray inspection improves operational efficiency, reduces inspection times, and enhances overall product safety and quality assurance standards.

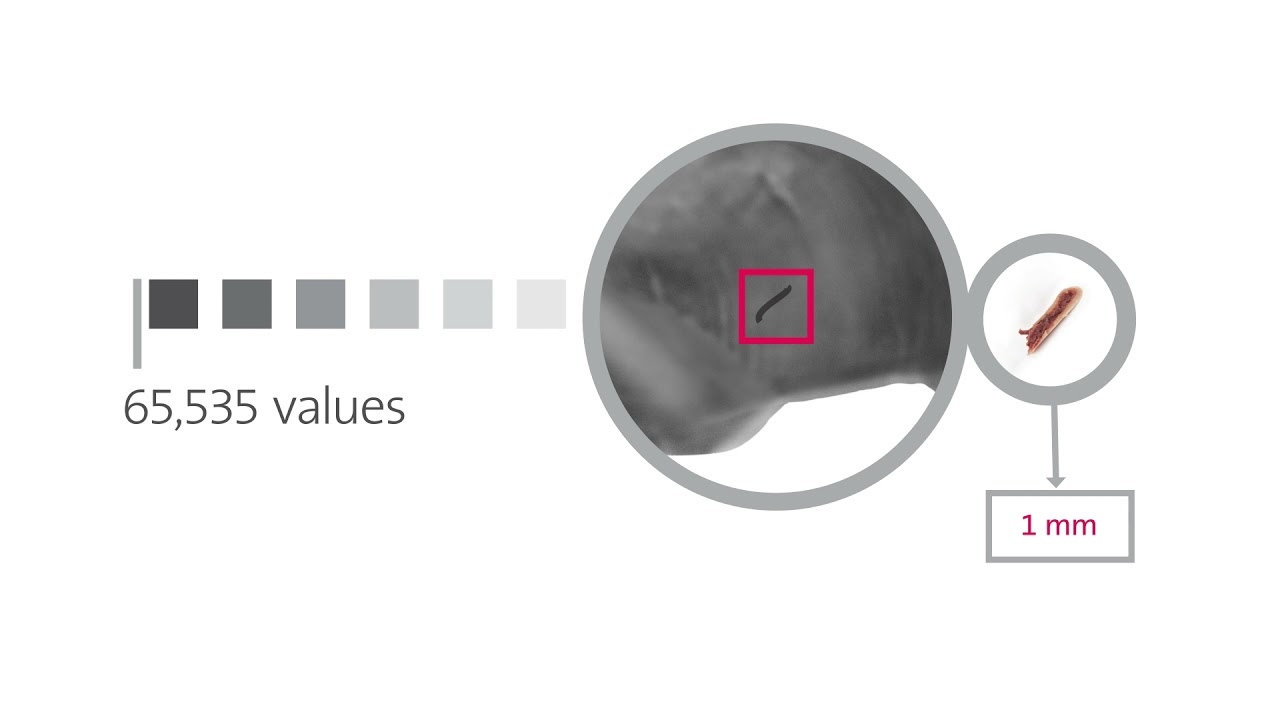

Our PXT™ dual energy photon-counting technology, combined with SimulTask™ PRO image analysis software, delivers high-resolution images and real-time analysis in just one-tenth of a second, setting a new standard in detecting bones and contaminants. Eagle Product Inspection focuses on developing advanced x-ray analysis solutions for superior product inspection.

PXT™ dual energy photon-counting x-ray detector for bone inspection provides unmatched performance for the next generation of food processing and delivers superior poultry bone and contamination detection. PXT™ enables processors to obtain much higher resolution images by capturing more detailed data about the product being inspected than has previously been possible. Beyond that, with the new PXT™ technology you will ultimately get a superior return on your investment, including:

SimulTask™ PRO advanced imaging software simultaneously detects contaminants and performs multiple quality control checks. With the highest grayscale range in the industry (0-65,535) it delivers high resolution images with deeper contrast, exceptional clarity and extraordinary detail.

Eagle’s TraceServer™ x-ray software stores valuable production data and machine status information from one or more of Eagle’s x-ray machines and consolidates it into a single centralized database. The software seamlessly records inspection processes, which in turn contributes to your ability to meet established internal quality standards. It is scalable to meet your company’s needs and can connect up to 32 x-ray machines at once, making product traceability effortless.

Eagle experts can help configure the best x-ray or fat analysis machine for your product application, inspection needs, and production environment. Send us your product for a free test, and you’ll receive a detailed report with machine configuration, inspection data, and the Probability of Detection (POD) as a percentage, reflecting real production conditions.

Superior x-ray inspection technology provides outstanding detection of physical contaminants regardless of their size, shape or location within a product.

Mass and weight measurement with x-ray technology provides an additional layer of process control and due diligence to ensure a high-quality.

Package integrity is a vital quality control issue, it is essential to identify and reject deformed packages and also critically important that seals remain airtight to ensure freshness of food products.

Ensuring proper component count with x-ray technology is quicker and far more reliable than other inspection methods because x-ray systems can look inside sealed packaging for verification.

In addition to providing industry-leading technology and unparalleled reliability, Eagle provides highly-responsive support and service coverage globally, through a network of expert partners, supported by a core team of regionally-based Eagle experts.

Learn how to choose the right x-ray detector technology, the key factors and benefits to optimize performance for your line in this OnDemand webinar.

Find out the benefits x-ray inspection equipment offers to the food industry over metal detectors and why it’s the right choice for your line.

Ensure contaminant detection, product fill level, mass measurement, package integrity, component count and more with x-ray inspection technology.

What Our Customers Say