Dairy Quality Assurance & Food Safety with Advanced Inspection

Dairy producers face unique application challenges with many shapes, sizes, densities, and packaging for a variety of products.

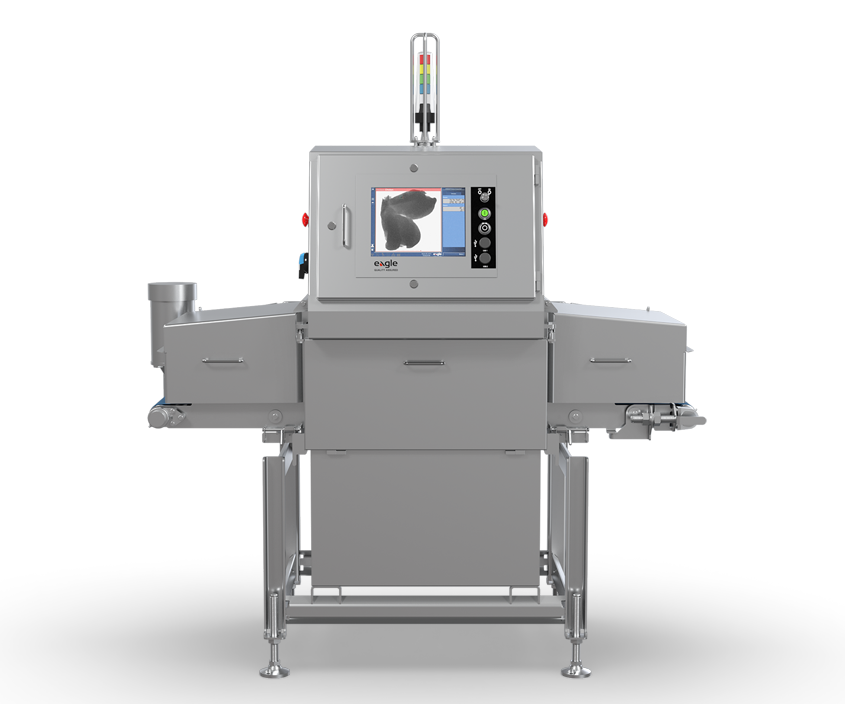

Eagle’s advanced inspection systems help manufacturers inspect more, finding foreign contaminants and ensuring proper portioning, placement, weight and package integrity to deliver the safest, highest quality products.

.svg)