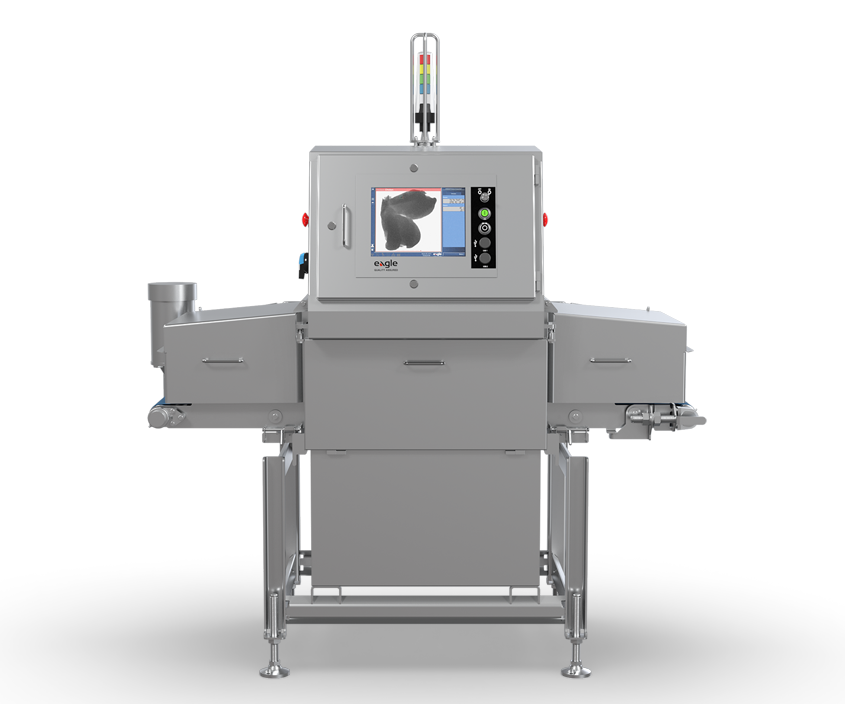

Seafood X-ray Inspection System

Eagle PI’s advanced seafood x-ray inspection systems, featuring our innovative PXT™ dual-energy photon-counting x-ray detector, empower seafood manufacturers to enhance inspection accuracy and detect more contaminants during fish processing. This ensures superior quality control in the food industry while optimizing overall business performance.

.svg)