Adjustable mechanical variations

Allowing for adjustments in your raw or unpackaged variables

No matter how meat processing companies slice it, grind it, package it or transport it, Eagle Product Inspection has fat analysis and inline x-ray food inspection solutions for a variety of processed red meat. This includes trim and primal cuts, sausages, ground meats, bone-in products, case-ready meats and countless other meat packaging types.

Explore our meat analysis technologies and learn more about our application specific range of solutions for beef, lamb and pork processing in various types of meat packaging. You will find that Eagle delivers the world’s #1 food safety and inspection service that red meat food processing companies trust.

This industry insight video explores how inline fat analysis takes the guesswork out of meat inspection by providing the most accurate chemical lean values. Read our ebook to learn more about the benefits of inline fat analysis for slaughterhouses and further processors.

Whether trying to conform to a HARPC based program like FSMA or a GFSI HACCP, having Eagle x-ray systems on your line with advanced traceability software, like Eagle’s TraceServer™, will provide measures and documentation essential to compliance. Click below to learn how an Eagle x-ray machine equipped with TraceServer™ provides companies with due diligence capabilities.

See the unique features of the FA3/M fat analysis system that ensure precise fat measurement, detection accuracy and maximum uptime such as UPSHOT™, SimulTask™ PRO image analysis software and more. Click below to learn more about the industry’s most accurate inline fat analysis system.

Keeping your x-ray or fat analysis machine running at peak performance over its lifetime requires a partner that understands how to ensure its longevity from initial start up to the final run. Eagle’s service and support packages focus on a low total cost of ownership. Click the link below to learn more about the 5 customer support solutions designed for maximum machine uptime.

Eagle experts can help configure the best x-ray or fat analysis machine for your product application, inspection needs, and production environment. Send us your product for a free test, and you’ll receive a detailed report with machine configuration, inspection data, and the Probability of Detection (POD) as a percentage, reflecting real production conditions.

Request Information

Please fill out the form with supporting details and a representative will contact you. Required fields are noted with an asterisk.

"*" indicates required fields

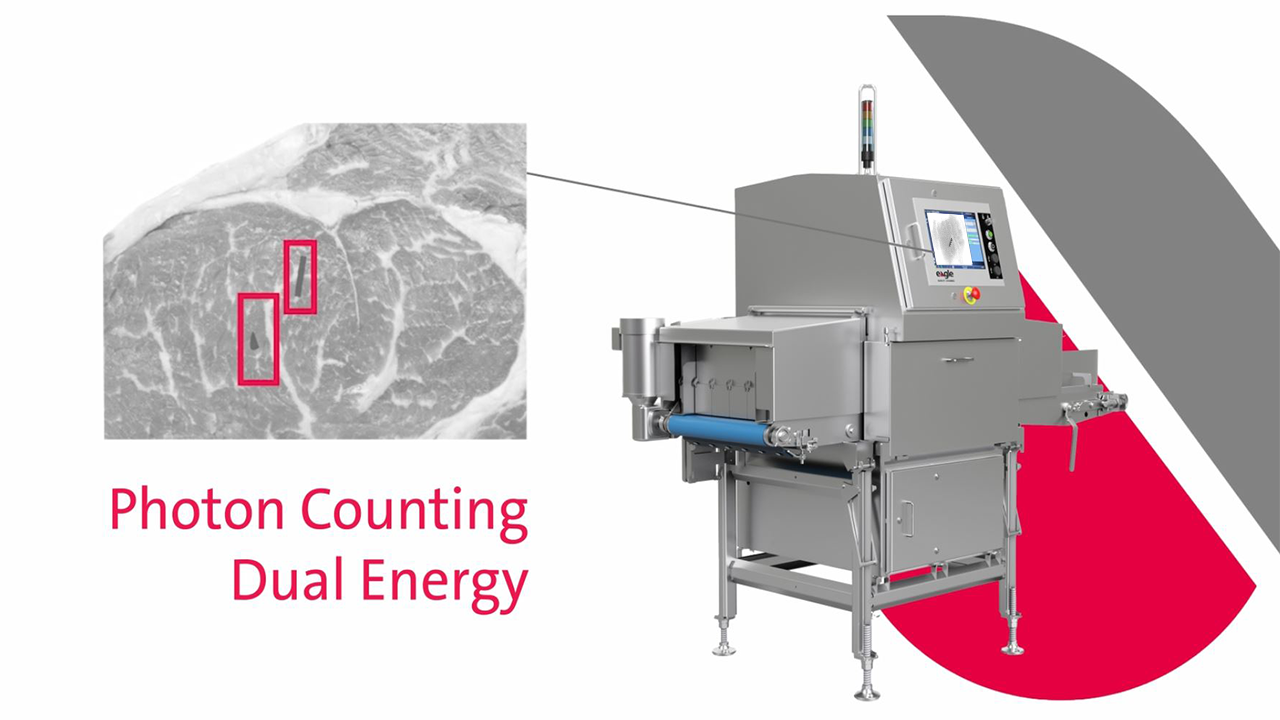

Our PXT™ dual energy photon-counting technology, combined with SimulTask™ PRO image analysis software, delivers high-resolution images and real-time analysis in just one-tenth of a second, setting a new standard in detecting bones and contaminants. Eagle Product Inspection focuses on developing advanced x-ray analysis solutions for superior product inspection.

Exclusive to Eagle, this radically enhanced dual energy detector captures more detailed information about a product than previously possible. When this product information is instantly processed by Eagle’s advanced image analysis software, SimulTask PRO™, you’ll see higher resolution images, an increase in detection accuracy and significantly reduced false reject rates.

SimulTask™ PRO, short for Simultaneous Tasking, is Eagle’s advanced x-ray image analysis software which serves as the basis for all our operator-friendly x-ray inspection systems. With the highest greyscale range of 65,535 values, you will see deeper contrast and subtle differences that provide superior image results.

The Eagle TraceServer™ x-ray software program records valuable production data and machine status information from one or more of Eagle’s x-ray machines and consolidates it into a single centralized database. This intelligent software provides companies with due-diligence capabilities to enhance product traceability and overall quality assurance.

Material Discrimination X-ray, MDX is Eagle’s original dual energy technology that provides better detection for objects that show a very small x-ray absorption variation. Dense foreign bodies in dense products are more easily detected using MDX compared to single energy detectors.

Our Dual Energy X-ray Absorptiometry (DEXA) technology inspects 100% of throughput in real-time, providing fat measurement accuracy better than +/- 1CL, while simultaneously verifying mass and detecting physical contaminants.

Allowing for adjustments in your raw or unpackaged variables

Vast material handling enabling a wide variety of meat types from fresh to frozen, unpackaged and packaged

Eagle x-ray food inspection image analysis with the widest grey scale range revealing more physical contamination that may be in your product

Graphical displays provide real-time production data for more accuracy

Experience multiple benefits when linking your fat analysis to your inspection process

Benefit from fat analysis process optimization and improvements in food quality control

Dual Energy enhances traditional x-ray food inspection and allows for the detection of materials previously unseen by single energy x-ray.

100% meat inspection provides precise chemical lean values to better than +/- 1 CL.

Superior x-ray food inspection technology provides outstanding detection of physical contamination regardless of their size, shape or location within a product.

Maintaining the correct fill level is crucial for food quality control, customer satisfaction and your profit margin.

Mass and weight measurement with x-ray food inspection technology provides an additional layer of process control and due diligence to ensure a high-quality.

Package integrity is essential to identify and reject deformed packages and also critically important that seals remain airtight to ensure freshness of food products.

Ensuring proper component count with x-ray food inspection technology is quicker and far more reliable than other inspection methods because x-ray systems can look inside sealed packaging for verification.

As part of a complete solution, Eagle PI fat analysis machines provide accurate measurements of 100% of meat throughput to improve yields, enhance product quality and maximize profits.

Send us a sample of your product and we will show you what our red meat x-ray inspection systems can do.

Witness firsthand the clarity of our x-ray images and the breadth of our inspection capabilities.

"*" indicates required fields

Our product guide features each of our x-ray and fat analysis systems, along with their specific capabilities, and is designed to help manufacturers find the optimal solution for their individual needs.

Essential reading for anyone involved in the production or processing of meat.

Eagle’s Pack 400 HC helps ground meat chub manufacturers maximize yields and increase profitability.