Superior

Contaminant Detection

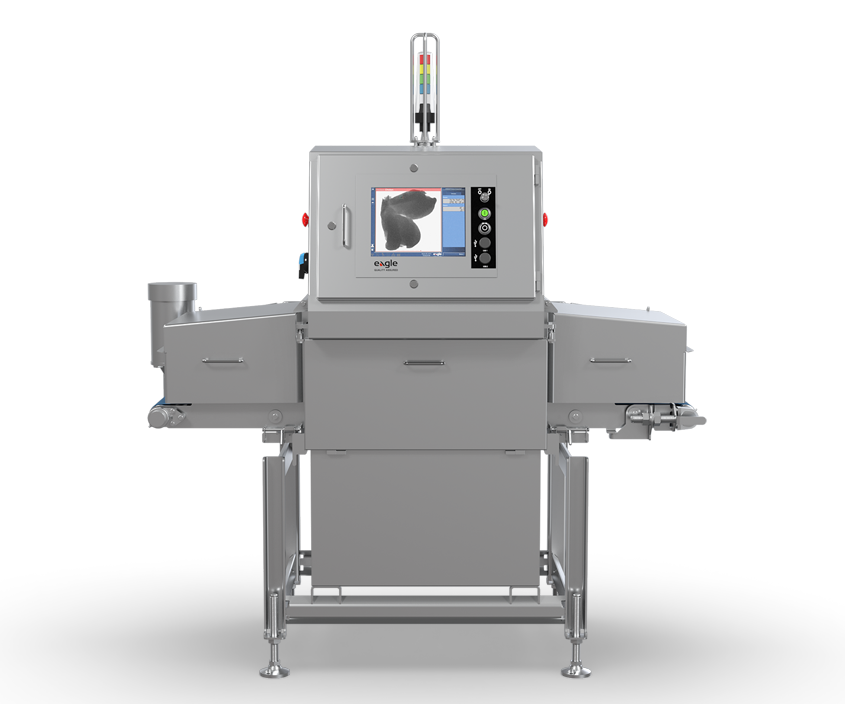

X-ray systems provide superior contaminant detection

Combining best-in-class physical machine design with multiple generator and detector configurations, and SimulTask™ PRO imaging software, you get the best food x ray inspection equipment for your production line. Eagle Product Inspection offers multiple detector configurations and sizes with diode options to fit your specific needs, application requirements, and food manufacturing standards, delivering superior food contamination detection of the following physical contaminants:

- Glass

- Metal fragments

- Mineral stone

- Calcified bone

- Some plastic and rubber compounds

Foreign Body Contaminant Detection

Bone Detection

Stone Detection

Glass Detection

Metal Detection

Plastic Detection

Bone Detection

Bone Detection

Eagle x-ray systems are capable of detecting down to 2 mm bone but when paired with the new PXT™ photon-counting detector our machines can locate bone fragments down to 1 mm in poultry products and .5 mm in fish fillets. Locate the smallest of bone fragments in chicken, fish and red meat products with high resolution image analysis for reliable results and fewer false rejects.

Stone Detection

Stone Detection

Stone contaminants can pose several safety risks and Eagle’s dual energy inspection systems provide excellent detection of stones particularly in multi-textured foods like mixed nuts and cereal. See how the Eagle Bulk 415 PRO with MDX dual energy technology easily discriminates between fig product and stones that are mixed together at harvest but would go unseen to the naked eye.

Glass Detection

Glass Detection

Glass packaging has risen in popularity and is used for a wide range of applications. But glass packaging poses a significant safety risk and the effects of glass-in-glass contamination can be highly damaging. Eagle’s four view inspection system detects tiny glass contaminants in the side walls and bottom crevasses of tall rigid containers safeguarding food products and brand reputation.

Metal Detection

Metal Detection

Eagle systems are capable of x ray metal detector in a broad range of applications and packaging types. Unlike traditional inspection systems, x-ray can see straight through low-density foil or metalized film to obtain a better view of metal contaminants. Find out how x-ray inspection machines can reduce your false reject rate and optimize your product inspection line for maximum results.

Plastic Detection

Plastic Detection

Eagle x-ray inspection systems are capable of detecting some plastics and rubbers. However, dual energy (MDX) technology is often better suited for plastic detection, particularly in bulk and packaged food products like bags of mixed salad leaves, cereals, nuts and confectionery, all of which contain high variations in density.

Reliable Results for Your Production Line

Get the most for your line with x ray inspection systems food industry.

CONSISTENCY

RELIABILITY

REDUCED DOWNTIME

HIGHER THROUGHPUT

SUPERIOR PRODUCT QUALITY

LOWER COST OF OWNERSHIP

HYGIENIC DESIGN

Advanced X-Ray Inspection Systems

Superior intelligence. Superior Results.

SimulTask™ PRO advanced image analysis software takes the guesswork out of food x ray imaging to focus on safety, quality, operational efficiency and profitability.

How Safe is X-ray Inspection?

Find out how x ray food inspection systems deliver safe and effective product inspection with repeatable and reliable results for a multitude of contaminants.

Top 10 Frequently Asked Questions for X-ray Inspection

Get answers to the most frequently asked questions for x-ray product inspection! Find out how Eagle’s x-ray machines combined with our sophisticated software deliver the highest resolution images in the x ray inspection food industry with the greatest amount of detail for reliable food contaminant detection.

Learn how the combination of robust hygienic construction and advanced software allow for a wide range of detection to prevent product recalls, saving processors time and labor on their lines.

Eagle Industries

Red Meat

Poultry

Seafood

Dairy

Fruits & Vegetables

OEM & System Integrators

Red Meat

Red Meat

At Eagle PI, we build robust, easy-to-manage meat inspection and fat analysis systems that conform to your unique product line. From raw product to case inspection, our photon-counting and inline fat analysis technology gives you the ability to inspect 100% of your throughput in real-time. With a margin of error better than ±1 CL, our machines deliver precise chemical lean measurements that are vital for maintaining compliance and customer satisfaction.

Poultry

Poultry

Eagle provides advanced x-ray technologies and inspection systems for a variety of poultry applications, from the receipt of bulk-flow raw product, through in-process to final packaged product. Our hygienically constructed x-ray machines with photon-counting technology are suited for a variety of poultry applications. Discover our broad range of solutions with significant proven performance for superior detection of bones and other contaminants.

Seafood

Seafood

Catch and remove contaminants before they pose problems with Eagle’s hygienically constructed equipment. Our advanced inspection systems and PXT™ photon-counting detector technology, helps seafood manufacturers inspect more, ensuring superior quality while optimizing business performance. Applications include frozen fish fillets or blocks, canned or metalized pouches and bulk shelled products.

Dairy

Dairy

Eagle’s advanced inspection systems can detect foreign contaminants in a multitude of dairy products, from raw cheese blocks to packaged yogurts. Our hygienically constructed equipment built to sanitary design can also ensure proper portioning, placement of product, weight and package integrity to deliver the safest, highest quality products.

Fruits & Vegetables

Fruits & Vegetables

Whether it’s detecting glass fragments in glass jars of jelly, plastic in a frozen bag of corn or metal in the bottom of a pickled vegetable jar, Eagle x-ray systems provide outstanding detection. With advanced dual energy technology our systems can detect contaminants in dense foods, such as dried bulk fruit, and generate easy-to-read images for enhanced analysis.

OEM & System Integrators

OEM & System Integrators

Eagle is a trust worthy brand, committed to building technology and x-ray inspection equipment with integrity. We pride ourselves on our proven success in various industries with reliable and repeatable results. We don’t just sell machines; we build lasting relationships to ensure your customer base is well served. Learn more about the benefits of choosing Eagle x-ray inspection for your customers.

Talk to AN EXPERT

Have questions? Just ask us.

Please fill out the form with application details and a representative will contact you about food inspection x ray.

"*" indicates required fields

Industry Resources

Advanced Inspection Technologies in Processing

Eagle’s PXT™ detector revolutionizes bone detection in red meat, poultry, and seafood with high accuracy and reduced false reject rates.

5 Steps to Improve Quality Management with X-ray Inspection Equipment

Learn how x-ray inspection equipment can improve your quality management program in a way that enhances both quality control and quality assurance.

9 Ways X-ray Technology Positions You for Success

Learn the many ways that x-ray inspection can simplify your food safety audits with easy retrieval auditing reports, time-stamped imaging and more!

.svg)